Implementing an Enterprise Resource Planning (ERP) system, such as SAP, JD Edwards or Oracle Netsuite, is a significant financial investment, particularly if the implementation is global in scale and involves multiple business units. While the benefits of an effective ERP system can outweigh the high cost of implementation, challenges invariably arise when companies grow via mergers or acquisitions or into new markets. In such situations, achieving short-term commercial goals is often prioritized over ERP considerations.. This can lead to system customizations and process workarounds that meet short-term objectives but that erode the original benefits of the ERP implementation by adding additional costs and complexity. These workarounds eventually become codified in standard operating procedures, additional technology is built upon the existing foundation, and the technical debt compounds rapidly, eventually outstripping any efficiency gained by the ERP system in the first place.

Companies end up with complicated, disparate product, customer and vendor master data that result in complex or ineffective offline operational and financial reporting. This may also result in “data silos" by business unit, further undermining the benefits of an integrated ERP. So, how do companies maximize their investment in these large ERP systems, while realizing the commercial benefit of new business integrations? How do companies unravel established workarounds and system customizations without risking a negative impact on the business?

In order to undo this “system erosion” of poorly executed integration projects, companies must adopt an approach built on Lean and Continuous Improvement principles that consider both process requirements and installed ERP system capabilities. This approach is supported by a measured, phased program methodology focused on delivering business value by considering ERP system capabilities - integrated across all (new and existing) business units of the company.

Continuous Improvement is a management / operational framework whereby organizations, business units, and individual teams methodically and routinely analyze and refine their respective operations to ensure that they align with and support the overarching strategic objective of the organization to the greatest degree possible.

Lean is a formal Continuous Improvement practice that focuses on eliminating waste and maximizing efficiency in business processes. Some of the specific Lean principles that apply to this approach are:

- Value: Identifying and focusing on the value that the ERP system can bring in simplifying and standardizing processes and data across the organization. Examples: Rationalizing master data to reduce duplication; automating workflow to simplify processes across functions.

- Flow: Identifying and eliminating any bottlenecks or delays that impede the flow of information and processes across the organization Example: Ensuring all data have a single system of record; application interfaces with the ERP are seamlessly integrated.

- Pull: Prioritizing and implementing changes based on the needs and priorities of the business and customers. Understand business rules and ensure these are configured in the ERP.

- Perfection: Continuously identifying and addressing inefficiencies in processes and ERP technologies. Continually assess system performance against business objectives.

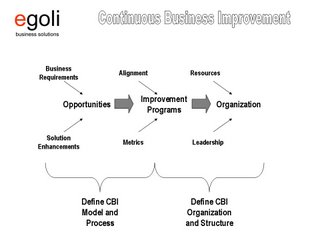

The Lean model for ERP improvement projects is built on these 3 key steps:

- Define Areas of Improvement

- Gather information from process experts to understand the problem to be solved

- Understand business requirements in terms of functional specifications and business rules

- Understand the ERP capabilities related to these requirements so that technical requirements are specified

- Execute Improvement Projects

- Prioritize the identified opportunities with defined business objectives

- Create a program plan for delivering sustainable improvements

- Ensure agreed targets are met

- Create Culture of Continuous Improvement

- Obtain executive sponsorship and leadership around these projects

- Dedicate the necessary resources to deliver improvements

- Organize around value creation from existing system capabilities

Fixing ERP system erosion cannot be addressed by fixing one-off issues based on the loudest voice pushing support tickets through the IT Support group. Fixing ERP system erosion sustainably relies on following the approach of Lean / Continuous Improvement described above. This approach guarantees that fixes are permanent and that business value is front and center of prioritizing system improvements. Over time, your ERP system will become fully utilized to drive the business benefits that were promised when it was first implemented!